The opinions expressed here by Trellis expert contributors are their own, not those of Trellis.

![]()

At the start of 2025, if you asked chief sustainability officers what their primary role was, the answer was to continue to push for change, get their executive leadership onboard and make the business case to integrate sustainability into corporate infrastructure. The Weinreb Group asked this very question and published their perspective, which largely noted that they anticipated staying the course in the years to come.

On one hand, that prediction was accurate: commitments to corporate sustainability have remained largely unchanged despite considerable financial, political and societal headwinds. In fact, many companies have deepened their commitments. What has changed, however, are two key shifts, both of which directly impact the professional overall.

The first is a shift in messaging from external communications to internal ones. While the work is still happening, the desire to promote it in the current environment has both waned and changed course dramatically. Instead of touting climate or social impact, today’s communications are more internally-focused and place a much greater emphasis on business benefits.

The second and related change is that sustainability has shifted towards primarily being a legal and regulatory function within organizations. The result of these two changes is that the role of the CSO and all sustainability professionals have also morphed in terms of messaging and reporting relationships.

The evolution of messaging

Long gone are the days when the CEO and CSO would stand on stage for an all-employee meeting and tout the virtues of sustainability while tying commitments to that CEO’s legacy. The shift was chronicled in a report from Deloitte, which noted that “CEOs are focusing on cost management, supply chain resilience and AI to drive sustainable growth.”

This shift is indicative of a broader industry change we’re seeing: company leaders are prioritizing business value over impact. The emphasis has gone from “show me the impact and money” to “show me the money.”

Of course, many sustainability professionals have been making the business case for years. But the message often hasn’t made it through, because of:

- Opponents’ messaging: Sustainability opponents have worked hard to paint sustainability as a profit-killer, with efforts ramping up in recent years to depict sustainability as a lever that dilutes shareholder value.

- Absence from high-profile communications: Financial impacts are often left out of sustainability messages. For example, Cambridge University and BCG found half of the speeches at COPs 27 through 29 didn’t mention economic impacts at all. Tensie Whelan of New York University told Trellis, “ESG reporting metrics neither integrate financial performance nor provide guidance on how to understand and drive better financial performance.”

- Missing the cost of inaction: The cost of inaction is consistently vastly underestimated. Although it can be quantified, very few companies do so because they don’t know how to do it or how to get the CFO on board. This makes it look like inaction is costless, although nothing could be farther from the truth.

The reality of a regulatory role

When it comes to reporting relationships, CEOs’ prioritizing efficiency over impact has changed things. In general, CSO reporting lines are further from the CEO, and there’s a strong emphasis on CSOs working to mitigate legal risk. The Weinreb Group’s most recent CSO report found the number of CSOs reporting into the legal department has doubled in just the last two years. And the role of ESG controllers rose in 2024 because of their ability to apply financial analysis to non-financial data, such as climate risk.

In addition, sustainability teams are increasingly being disbanded and distributed across business functions. This year, we’ve seen heads of sustainability depart from Nike, Unilever and Apple while their responsibilities have dispersed elsewhere

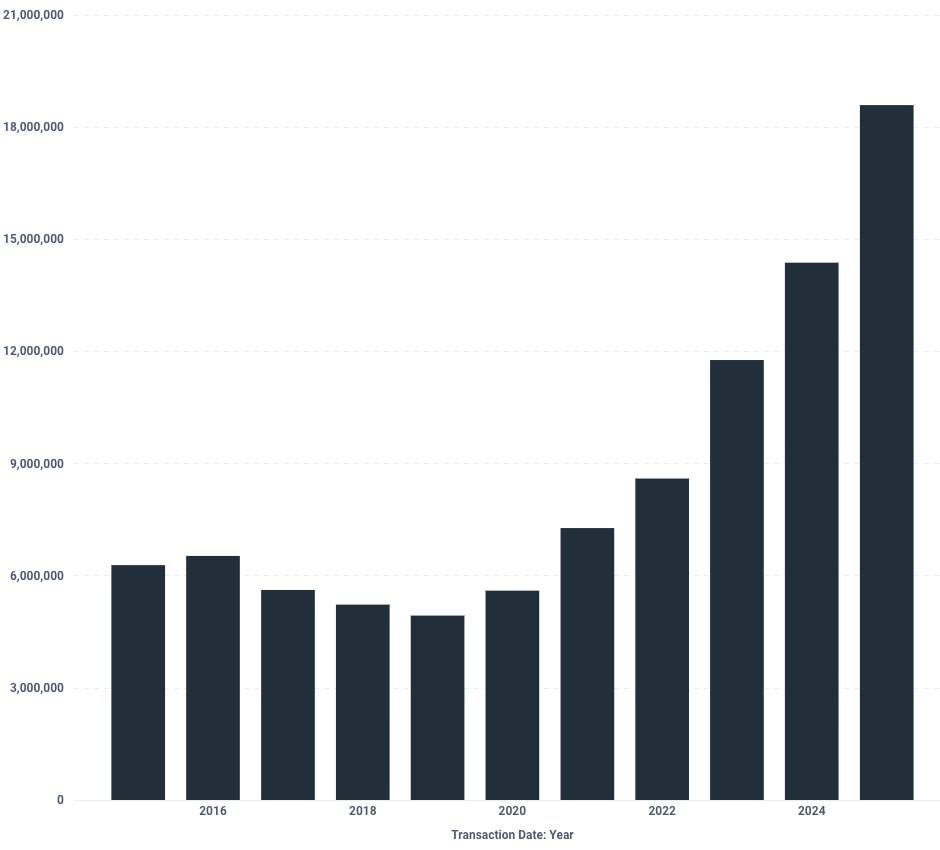

Greenwashing, too, has evolved from being a marketing issue to a legal one through the dramatic rise in global legislative initiatives that have cost companies millions. Just this month, for example, the UK banned ads from 3 major clothing brands, citing misleading green claims.

The sustainability job in 2026

Where does this leave sustainability leaders? We have five suggestions for how to lead in today’s regulatory-driven environment:

- Take an auditor to lunch. Given the increased expectation for data to be verified and assured, you don’t have to become an auditor, but you should get to know the ones your company uses. Find out what they prioritize and how they think, so you can align your strategy accordingly. The relationship you build will help you both.

- Track lobbying efforts. Corporate lobbying in opposition to sustainability rules rose this year, and that is likely to continue. It’s important to stay apprised of such efforts, because they could significantly affect regulatory changes that aim to keep climate law and human rights efforts intact. Keeping an eye on developments specific to your industry will make you smarter and able to ask the right questions.

- Embrace AI and big data. It’s easy to dismiss AI as a tech issue, or avoid it because of concerns about how it consumes resources. But AI isn’t going anywhere and the professionals who gain an understanding of its benefits and how to apply it to climate strategies will have an advantage going forward.

- Tell your stories, but differently. Storytelling is one of the oldest and most enduring formats of societal change. To be heard, you’ll have to evolve the language you use to ensure non-partisan engagement. And you’ll also need to emphasize business benefits to overcome current messaging challenges. This may look difficult, but don’t give up on the power of creating a narrative that communicates progress, value and impact.

- Don’t lose sight of the human side of sustainability. While the emphasis right now is on policy and efficiency, at the end of the day sustainability is about our ability to ensure a healthy, equitable and thriving planet for all people.

There’s no question sustainability is an enduring profession. It’s been through many pendulum swings over the past decades, and we can guarantee we’ll see many more. Your job isn’t to become everything to everyone, but to double down on your resilience and meet the needs of today.

The post How sustainability leaders can get ahead in 2026 appeared first on Trellis.